KAPSOM is committed to developing innovative electronic methanol technology, a distinctive feature of which is extremely low energy consumption. We lead the sustainable development of the electronic methanol industry and optimize energy utilization to the extreme by adopting the most advanced low-energy technology.

Throughout the production process, we carefully design and integrate advanced energy-saving equipment and intelligent control systems to minimize power consumption. Not only does this help increase productivity and reduce operating costs, it is also consistent with our commitment to environmental sustainability.

By finely regulating the power requirements of our production equipment, we ensure that we produce high-quality e-methanol while maintaining extremely low power consumption. This low-energy design concept not only helps reduce the dependence of the production process on electricity resources, but also has a positive impact on the company’s sustainability and environmental protection goals.

With its excellent structural design, long life cycle, precise size, high specific surface area and uniform packing density, KAPSOM’s innovative catalysts provide reliable catalytic support for industrial production processes and demonstrate excellent performance in multiple application fields.

Structural stability

KAPSOM’s innovative catalyst uses spherical caps designed at both ends to maintain structural stability during the working process.

Durable

The service life can reach 3 to 5 years, which reduces the frequency of catalyst replacement, improves production efficiency, and reduces maintenance costs.

KAPSOM’s electronic methanol technology focuses on maximizing operational flexibility to meet the diverse needs of customers and adapt to changing market conditions. We understand that flexibility is one of the keys to success in the energy industry, so we consider maximizing operational flexibility as one of our core design principles.

Our electronic methanol system uses advanced control and automation technology to allow real-time monitoring and adjustment of various parameters in the production process. This real-time feedback mechanism allows the system to quickly adapt to production changes, providing optimal performance. In addition, our system also supports the switching of multiple operating modes and production scales, allowing customers to adjust production plans according to actual needs and achieve a greater degree of flexibility.

In addition, we design with integration into other production equipment and systems in mind to ensure our e-methanol technology is compatible with existing industrial infrastructure, providing customers with a seamless integration experience. This integration not only improves the overall performance of the system, but also provides more room for future upgrades and expansions.

By maximizing operational flexibility, KAPSOM’s electronic methanol technology aims to provide customers with smarter, more efficient and sustainable production solutions, helping them stay ahead in a highly competitive market.

| HYDROGEN GENERATION UNIT | 4.6~5.5 kWh/Nm3 (DC) Hydrogen |

| Single Set Maximum Capacity | |

| 1000 Nm3/h (stable operation) | |

| Service Life: 160,000 hours |

| METHANOL SYNTHESIS UNIT | Low and Medium Pressure Reaction 3.0~5.0 MPa |

| 200~300℃ | |

| 10-1,200kt/a: Single Series Design | |

| Temperature Easy Control, Convenient & Effective | |

| Temperature Easy Control, Convenient & Effective |

| METHANOL SYNTHESIS CATALYST | Black Cylinder With Spherical Caps of Two Ends (CuO, ZnO and Al2O3) |

| Service Life: 3~5 years | |

| Size:中5mmx(4-5)mm | |

| Specific Surface Area: >60m2/g | |

| Bulk Density: 1.2 kg/L±0.05kg/L |

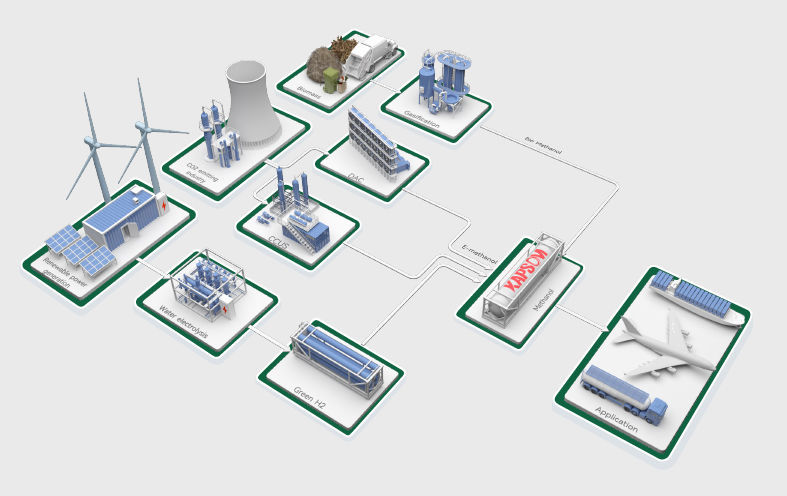

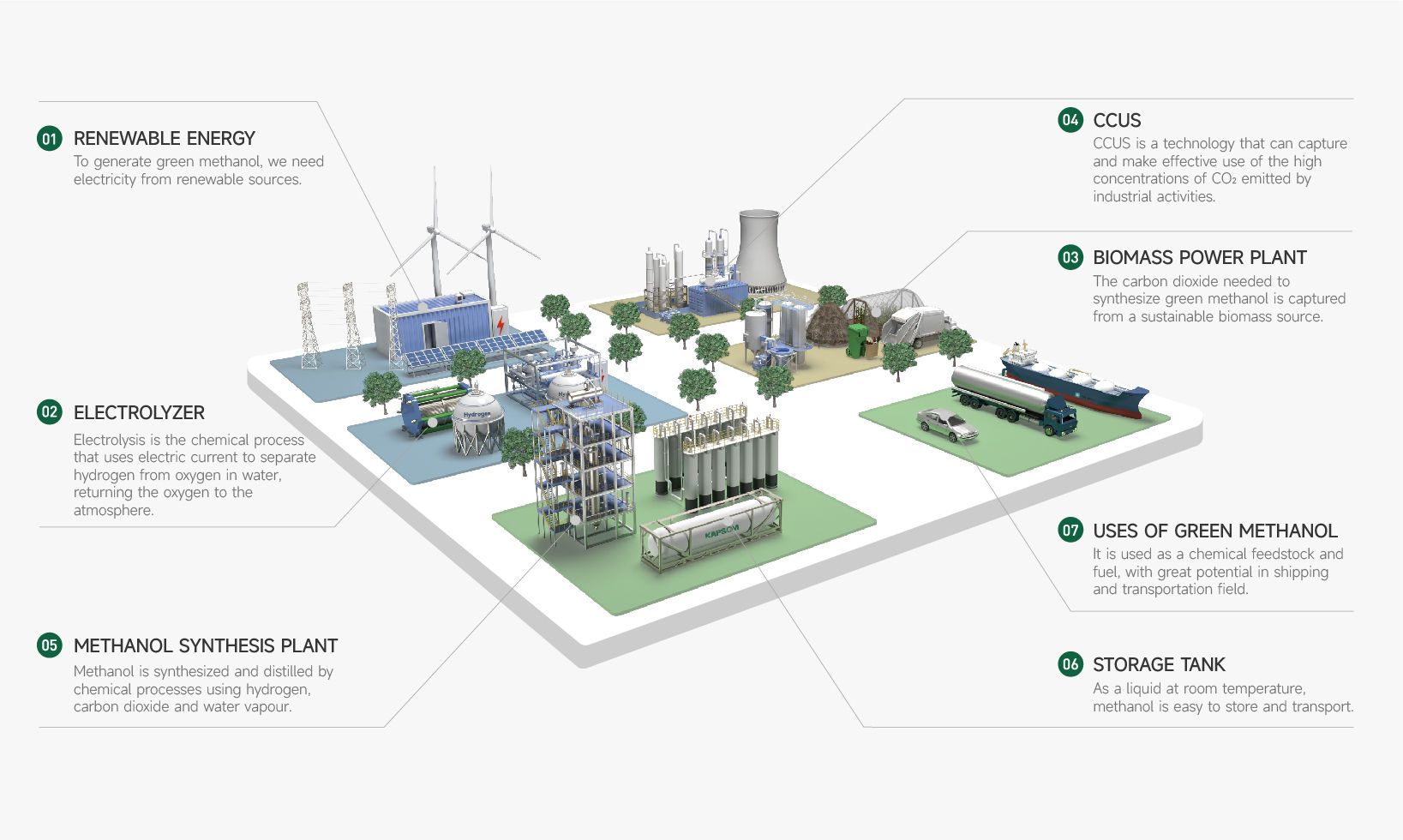

KAPSOM makes full use of renewable energy, such as solar and wind energy, to perform water electrolysis to generate environmentally friendly green hydrogen. Subsequently, electronic methanol was successfully synthesized by catalytically reacting this green hydrogen with carbon dioxide. This advanced preparation process not only significantly reduces reliance on traditional fossil fuels, but also effectively reduces the overall carbon footprint by using renewable energy. It is worth mentioning that the preparation of KAPSOM electronic methanol has excellent flexibility and can be applied to various scales and energy supply needs, from small distributed systems to large-scale industrial production, showing a wide range of applicability.

In June 2022, KAPSOM reached an agreement with a European company to undertake a green methanol project with an annual output of 50,000 tons. Renewable energy is used to decompose water to produce green hydrogen, and then methanol will be produced by adding green hydrogen to carbon dioxide. After the completion of the entire project, it will not only reduce carbon emissions, but also produce green and low-carbon fuels, greatly reduce the air pollution of enterprises and fully realize the high-value comprehensive utilization of resources.

In 2023, KAPSOM established a strategic partnership with Asia’sPGC New Energy Enterprises. The project aims to achieve an annual production target of 20,000 tons of green methanol through the use of plasma technology and green methanol processes. By integrating biomass green methanol production technology, plasma carbon conversion technology to reduce carbon dioxide emissions, and green hydrogen production technology via water electrolysis, this project is set to become a commercial exemplar in CCU (Carbon Capture and Utilization) operations, contributing to global carbon neutrality.

As a pioneer in green energy, e-methanol technology is not only committed to producing clean and renewable fuels, but also plays an important role in carbon capture and utilization (CCU). This technology uses innovative methods in the electronic methanol production process to effectively capture carbon dioxide in the atmosphere and then convert it into high value-added products to achieve sustainable utilization of carbon resources.

Carbon capture reduces greenhouse gas emissions by capturing carbon dioxide in exhaust gases during the production process and preventing it from being released into the atmosphere. Carbon utilization converts captured carbon dioxide into useful chemicals or fuels, enabling waste reuse and reducing the demand for traditional petrochemical resources.

E-Methanol’s carbon capture and utilization technology emphasizes innovation and sustainability. By integrating advanced catalysts and efficient reaction engineering, we are able to efficiently convert captured carbon dioxide into methanol while maintaining high product purity and quality.

This integrated approach to carbon capture and utilization not only helps reduce the environmental impact of the electronic methanol production process, but also provides a feasible technical path to achieve carbon neutrality and circular economy. Through continuous innovation, the development of electronic methanol technology in the field of carbon capture and utilization will continue to promote the progress of clean energy and contribute to a sustainable future.

The electronic methanol production process focuses on the full utilization of renewable energy, especially renewable electricity. We are committed to building a green and clean production ecosystem, using electricity from renewable energy sources such as solar energy and wind energy to provide sustainable power for the preparation of electronic methanol.

In the process, we capture nature’s abundant energy resources through advanced solar photovoltaic and wind power generation systems. The application of this renewable electricity aims to reduce the carbon footprint of overall production and reduce reliance on traditional electricity sources, thereby promoting the sustainable development of clean energy.

Electronic methanol technology is unique in the energy sector and is unique in that it enables a direct energy conversion process. Through advanced electrolysis and catalysis technology, we are able to directly convert renewable electricity and carbon dioxide into high-purity electronic methanol without going through tedious intermediate steps.

In the direct conversion of e-methanol, renewable electricity is used for the electrolysis of water to produce green hydrogen. Subsequently, this green hydrogen and carbon dioxide are directly converted into electronic methanol through an efficient catalytic reaction. This process is direct and efficient, greatly simplifying the complexity of energy conversion, while reducing energy loss and improving overall efficiency.

CO2 emissions from power plants, especially those that burn fossil fuels, can be a significant source. Capturing COz from the flue gas of power plants is a common approach.

Industrial processes such as steel and cement production release substantial amounts of CO2. Modules located near these facilities can capture and utilize CO2 emissions.

Municipal solid waste incineration releases CO2. Modules near waste treatment facilities can capture CO2 emissions generated during the incineration process.

Certain industrial processes release concentrated streams of CO2. Modules located near these processes can capture and use this CO2.

CO2 is often present in natural gas reservoirs. During natural gas processing, CO2 can be separated and utilized for electrochemical methanol synthesis.

If renewable hydrogen is produced through water electrolysis, the CO2 captured from the atmosphere or industrial processes can be used for methanol synthesis.