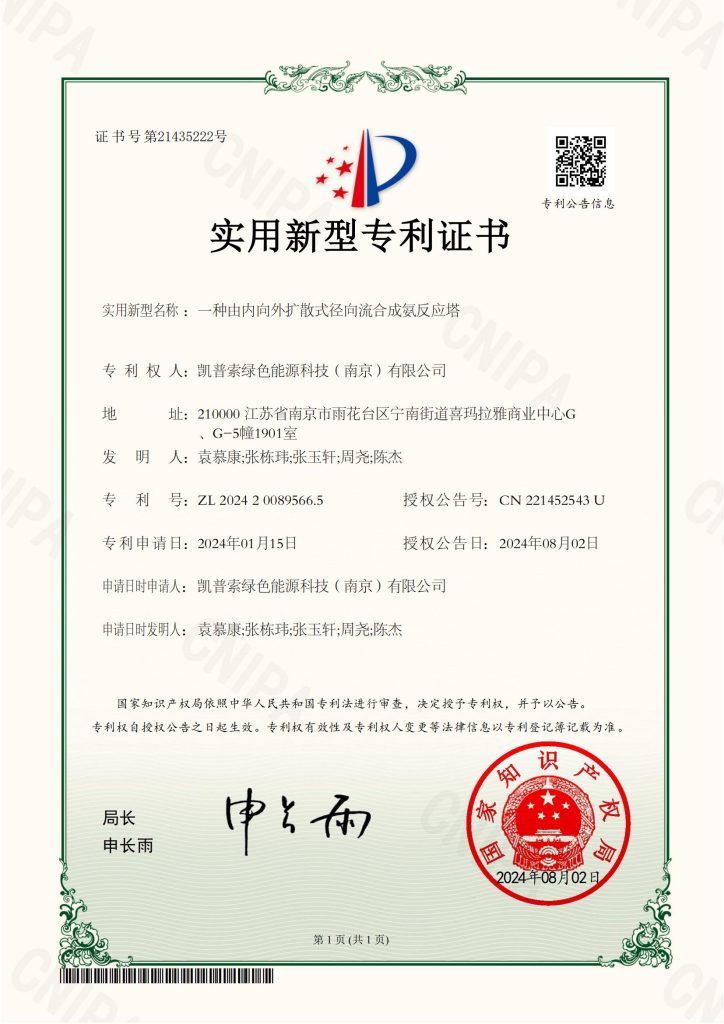

Recently, KAPSOM has been granted two utility model patents by the National Intellectual Property Administration of China. The newly approved patents are for “An Inward-to-Outward Diffusion Radial Flow Ammonia Synthesis Reactor” and “A Novel Axial Flow Ammonia Synthesis Reactor.” These patents mark significant advancements in KAPSOM’s commitment to innovative research and development in green energy technologies.

The Significance of Ammonia Synthesis

Ammonia is one of the most important inorganic chemical products, playing a crucial role in the national economy. Approximately 80% of ammonia is used in the production of chemical fertilizers, while the remaining 20% is utilized in manufacturing nitric acid, various nitrogen-containing inorganic salts, and organic intermediates. Additionally, some ammonia is employed as a refrigerant.

Ammonia synthesis units are chemical devices that synthesize ammonia from nitrogen and hydrogen under high temperature, high pressure, and the presence of a catalyst. As a vital component of modern chemical industries, ammonia synthesis plants not only support the production of agricultural fertilizers but also provide essential raw materials for fundamental organic chemistry.

Breakthrough Technological Innovations

The ammonia synthesis process requires specific conditions: first, the reaction must occur at a near-optimal temperature to achieve maximum production capacity and high ammonia yield. Second, the pressure drop in the reactor must be minimized to reduce the energy consumption of circulating gases. Lastly, the structure of the reactor must be simple and reliable, capable of withstanding high temperatures and pressures.

1. An Inward-to-Outward Diffusion Radial Flow Ammonia Synthesis Reactor

The current market’s radial flow ammonia synthesis reactors mainly consist of an outer channel, a catalyst bed, an inner channel, and a heat exchanger. In traditional designs, the reaction gases enter the catalyst bed through the outer channel and then flow through the inner channel towards the heat exchanger. However, because the aperture area of the inner channel is smaller than that of the outer channel, the flow rate of the reaction gases increases as they pass through the catalyst bed, resulting in reduced gas residence time and lower reaction efficiency.

To address these issues, KAPSOM has innovatively designed an inward-to-outward diffusion radial flow ammonia synthesis reactor. By optimizing the flow direction of the reaction gases and adjusting the aperture areas on the inner and outer walls of the catalyst bed, gases flow from the inside out through the catalyst bed. This design effectively reduces the flow rate and prolongs the gas residence time within the catalyst bed, significantly improving reaction efficiency.

2. A Novel Axial Flow Ammonia Synthesis Reactor

Conventional axial flow ammonia synthesis reactors primarily rely on the diffusion of reaction gases within the catalyst bed, which often results in uneven gas distribution and suboptimal reaction efficiency. KAPSOM’s novel axial flow ammonia synthesis reactor features an added distribution plate to enhance the uniform distribution of gases within the reactor, further improving reaction efficiency. Additionally, the design of the air vents ensures more uniform distribution of the heat exchange gases, contributing to better control of the catalyst bed temperature and creating more ideal reaction conditions.

Conclusion

The approval of these two patents will enhance our technological innovation capabilities and strengthen its competitive edge in the industry. Looking ahead, KAPSOM remains committed to the research and development of green energy technologies. We will continue to leverage its intellectual property in the design and manufacturing of green ammonia units, actively promoting the transformation of technological achievements and injecting new vitality into the industry’s growth.

For more information about KAPSOM and its initiatives, please contact dongling@kapsom.com.