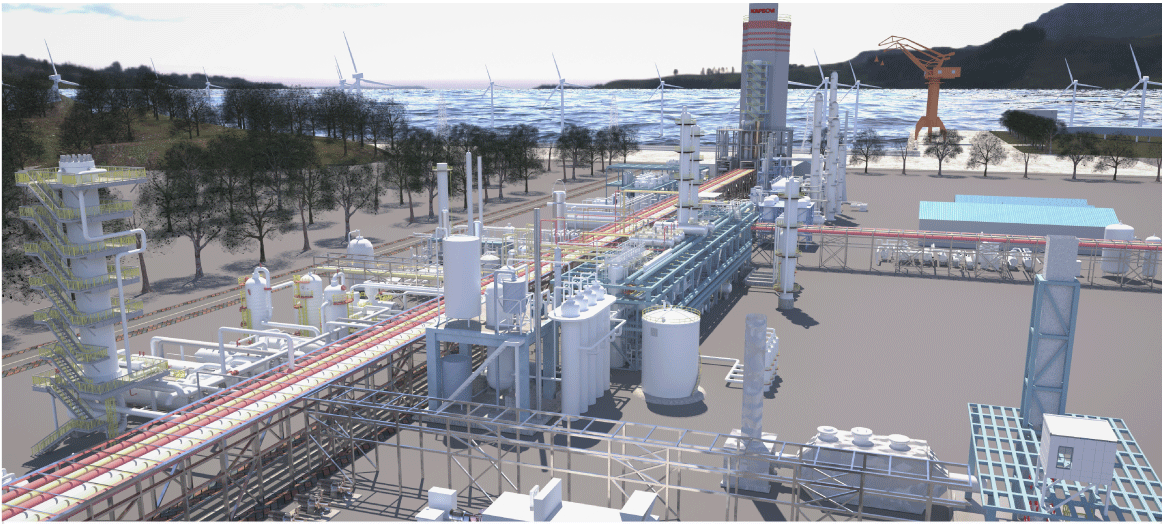

KAPSOM is the world’s leading provider of power-to-x solutions and delivered the world’s first green ammonia plant in 2021. Our mission is to make our world more sustainable every day by providing high-quality green chemical solutions, technologies and services that make our customers more successful and help sustain, decarbonize and protect our planet.

KAPSOM has always been committed to innovation and breakthroughs in green ammonia solutions. From the supply and operation of the world's first semi-commercial green ammonia plant to full-process services supporting demonstration plants in areas rich in natural resources such as scenery and water, we have always been at the forefront of the world. Integrated green ammonia solution, specially designed to protect your sustainable development transformation!

Blue ammonia is a compelling technological innovation designed to advance the sustainable use of ammonia. We have mature blue ammonia technology and are committed to expanding its application value chain. As an innovative hydrogen energy solution, blue ammonia provides strong support for mankind to achieve the goal of a zero-carbon economy by integrating advanced ammonia production technology and combining hydrogen energy with carbon capture and storage technology.

The production process of E-Methanol involves using electrical energy to catalytically reduce carbon dioxide and water to produce high-purity methanol without relying on traditional petroleum refining. This unique preparation method makes E-Methanol a green and sustainable liquid fuel, providing unprecedented opportunities to achieve energy transformation and build a low-carbon society.

By adopting biomass methanol technology, we can achieve sustainable utilization of biomass resources, mitigate dependence on traditional fossil fuels, reduce greenhouse gas emissions, and make positive contributions to climate change and sustainable energy development. The development of this technology not only promotes innovation in the energy industry, but also provides important support for building a cleaner and more sustainable energy future.

The use of green urea helps reduce the amount of nitrogen fertilizers applied, thereby lowering the concentration of nitrogen pollutants in soils and water bodies, mitigating the negative impacts on ecosystems, and aiding in the conservation of soil, water resources, and biodiversity. Green urea plays a significant role in agricultural development by promoting sustainability in agriculture.

KAPSOM specializes in delivering high-purity hydrogen through its innovative metal membrane low-temperature ammonia cracking technology. This method is tailored to the demands of high-tech sectors like hydrogen energy, nuclear energy, and semiconductors, featuring small-scale, decentralized, and compact equipment. Achieving conversion rates of up to 99.7% at temperatures between 500-600°C, with load capacities spanning from 30% to 100%.

Our footprint spans the world

If you want to join the decarbonization journey, whether to discuss projects or exchange ideas, please feel free to contact kapsom.