Exciting News! KAPSOM Awarded

National Utility Model Patent

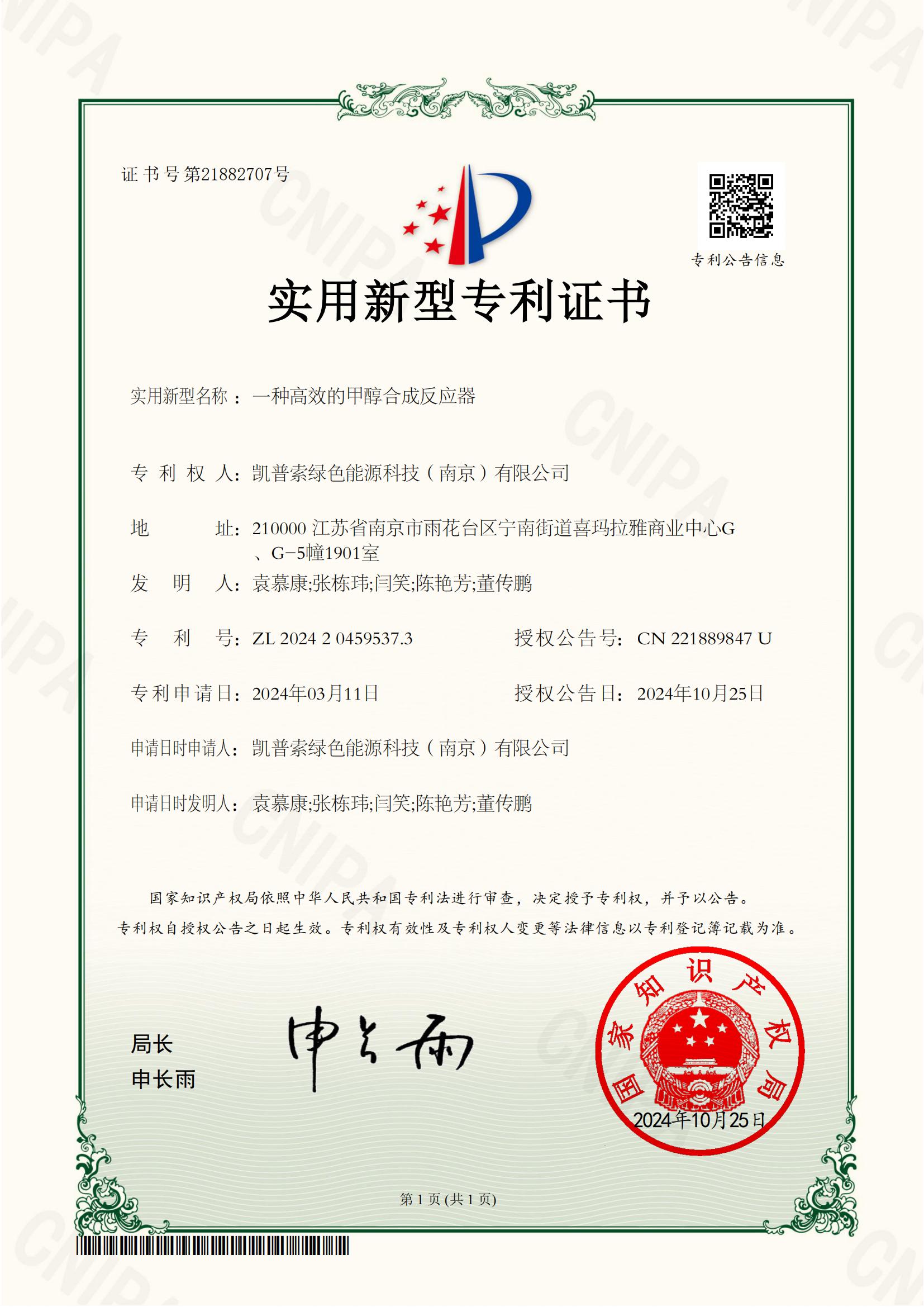

Recently, KAPSOM was awarded a Utility Model Patent by the Patent Examination Office of the China National Intellectual Property Administration (CNIPA). The patent, titled "An Efficient Methanol Synthesis Reactor," is registered under Patent No. ZL 2024 2 0459537.3. This achievement not only underscores the company's strong research and development capabilities but also marks another significant milestone in our pursuit of technological innovation.

In the chemical industry, methanol serves as a vital basic raw material with extensive application value. It plays a critical role in multiple fields, including pharmaceuticals, organic synthesis, and coatings, functioning as a precursor for the synthesis of numerous chemical products. Moreover, due to its low production cost and wide range of uses, methanol synthesis has become an integral part of the chemical industry. Methanol is not only used in the production of alcohols, ethers, and acid compounds but also demonstrates significant potential in fuel cells and clean energy applications.

Currently, the axial-flow methanol synthesis reactors widely used in the market primarily adopt a shell-and-tube design, similar to vertical shell-and-tube waste heat boilers, comprising a shell and heat exchange tubes. However, these reactors present several issues. Firstly, as the heat exchange tubes are straight, the reaction gas flows through them at a high velocity, resulting in insufficient contact time with the catalyst and subsequently affecting reaction efficiency. Secondly, the inner and outer surfaces of the heat exchange tubes are smooth, which leads to inadequate heat transfer between the reaction gas and the tubes. This insufficiency prevents the rapid removal of reaction heat, thereby impacting heat exchange efficiency and the stability of the catalytic reaction. Ultimately, these factors reduce the overall efficiency of the reactor system.

To address the limitations of existing technologies, the research and development team at KAPSOM has successfully developed an efficient methanol synthesis reactor through in-depth research and exploration. By improving the structure of the heat exchange tubes, the reactor significantly enhances the contact efficiency between the reaction gas and the catalyst, while improving heat transfer efficiency, thereby creating favorable conditions for increased production efficiency.

The modified structure of the inner and outer walls of the heat exchange tubes not only increases the turbulence of the reaction gas within the tubes, promoting more effective contact with the catalyst and thereby improving reaction efficiency, but also enhances the convective heat transfer effect between high-temperature gas and the inner walls of the tubes, further boosting the reactor's heat exchange performance. Additionally, the design increases the contact area between the outer wall of the heat exchange tubes and the heat transfer medium within the shell, optimizing convective heat transfer on the outer wall surface. This ensures the rapid and efficient dissipation of reaction heat, leading to a comprehensive improvement in the production efficiency of the entire system.

The granting of this invention patent not only serves as a powerful impetus for the company's continuous innovation and high-quality development but also injects strong momentum into the advancement of the green energy sector. Looking ahead, KAPSOM will remain committed to market-driven strategies and technology-driven innovation, continually exploring new technologies, processes, and applications. By doing so, we aim to contribute our expertise and efforts to the progress and development of the green energy industry.

Leave A Message

Scan to Wechat :